Guide to Cleaning and Lubricating Bearings

Regularly maintaining your bearings by cleaning and lubricating them is highly advisable to ensure they work at their best. Doing so will extend their durability and lifespan, providing enhanced speed.

Please Note: Keep away from water & sand.

The lifespan of bearings can significantly decrease if they are used or stored in moist and unclean conditions.

Steps for Cleaning and Lubricating Bearings in Skates, Skateboards, and Scooters

Step 1

Tools needed: A cleaning substance like a grease-dissolving fluid such as Fluid wash, a waterproof container, a pin or box cutter, a small brush, and fresh oil/grease.

Take the bearings out of the wheel. Refer to the YouTube video at the beginning for guidance on removing bearings from a wheel. Although the demonstration is on a skate, the procedure applies to skateboards and scooters as well.

Detach the wheels and remove the bearings.

Step 2

Utilise the brush to clean the exterior of the bearings, ensuring they are entirely free of dirt.

Bearings are of two varieties: open and closed. Open ones are simple to maintain, whereas closed ones require the shield to be removed with care.

Clean the exterior surfaces of the bearings.

Step 3

For sealed bearings, the seal can be taken off using a pin.

Some closed bearings with metal shields have a small C-clip that secures them, and this must be taken out with a pin before removing the shield.

Be sure to clean the seals and C-clips if applicable.

A pin or box cutter is used to detach seals (without C-clip) from the bearing.

Step 4

Put the bearings in a sealed container filled with the cleaning agent, then shake it for a few minutes. This will eliminate accumulated dirt.

Initially clean the bearings with a small brush, then apply the cleaning agent.

Step 5

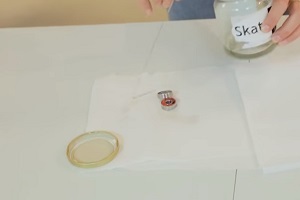

Extract the bearings from the container and dry off remaining cleaning agent by spinning them. An alternative is to use an air compressor to expel the fluid. Place the cleaned bearings on a section of clean fabric or kitchen roll.

The bearings have been extracted from the container with a cleaning solution.

Step 6

Assess if the cleaning has been effective. Hold the bearing by the inner ring and give it a gentle spin. If it doesn't turn smoothly or generates a gritty noise, it indicates incomplete cleaning. In such cases, repeat the cleaning process with a fresh batch of cleaning agent. For extensively dirty bearings, it might be necessary to repeat up to 2-3 times.

Spin the bearing to check if it is thoroughly clean.

Step 7

Return the bearings to the clean cloth or kitchen tissue. They are now ready for oil or grease application. Use 1-2 drops of oil (any more may attract dirt) or apply 3 mm of grease evenly around the bearing.

Ensure proper distribution of oil/grease by spinning the bearings, which can be expedited by fitting the bearing onto a drilling machine.

Carefully apply 1-2 drops of oil into the bearing.

Step 8

At last, reinstall the shields on the bearings and fit the bearings back into the wheels of the skate, skateboard, or stunt scooter.

Shields are refitted onto cleaned and lubricated bearings, which are then placed back onto the wheels.

Post-Cleaning and Lubrication

Following the cleaning and lubrication of the bearings, you might need to travel a few miles for the oil/grease to evenly distribute within the bearings, thereby achieving optimal performance.