Purchasing Wheels for Scooters

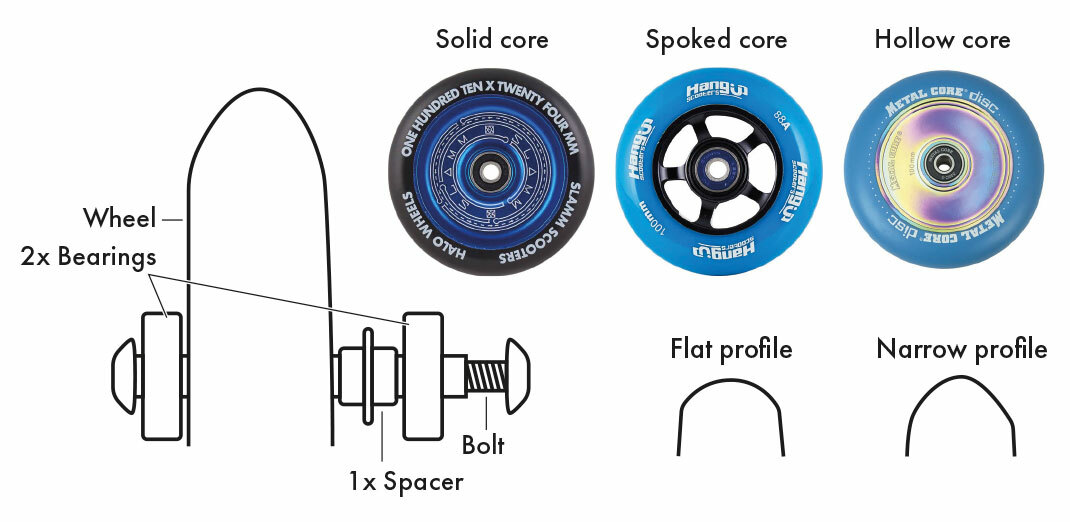

A functioning wheel requires two bearings and one spacer.

Wheels vary in materials, sizes, hardness levels, profiles, and core designs.

The following image clarifies each component.

Cores

- Solid core: A robust core designed for maximum durability.

- Spoked core: Features holes and cutouts, resulting in a lighter but less sturdy wheel.

- Hollow core: Lightweight due to its hollow interior, yet retains considerable strength, albeit not as much as a solid core.

- Plastic core: Not illustrated. These cores are somewhat flexible and have a shorter lifespan.

- Honeycomb core: Not illustrated. Utilises the same principle as the hollow core, but is lighter due to its perforations.

Profiles

- Flat profile: Offers strength to the rubber and maximum grip.

- Narrow profile: Designed for speed.

Hardness

- Measured on the durometer scale from 0-100a, with 100a being the hardest; most scooter wheels are rated 85a.

- Hard wheels have greater longevity, provide more speed, but are also more slippery.

- Soft wheels offer excellent grip and are ideal for parks and indoor use, although they wear down more quickly.

- If the manufacturer does not specify the wheel hardness, experimenting with it is advisable.

Installing Bearings in the Wheel

- Fitting bearings can be challenging; we offer a video guide for Installing bearings into a scooter wheel with a metal core here.

Tips

- Ensure bearings are perfectly aligned with the centre to avoid damaging both the bearings and the wheel centre.

- Using a hammer on the wheel or bearings during installation will nullify the warranty and your right to a claim.

- Wheels with a flat profile may not fit forks with a pointed profile at the front.

- Replace worn wheels for safety and to avoid damaging the Flex fender brake!

Claim or Due to Wear and Tear?

Wheels crafted for performing tricks are subjected to intense pressure and, like all wheels, possess limited durability.

Engaging in spins like tail whips or 360s exerts significant lateral pressure on the wheels. Repeated actions can cause material fractures or separations.

Determining if it's a claim issue or regular usage wear can be challenging.

Flat spots

Applying brakes suddenly and locking them while the wheel is forced against the tarmac can result in "flat spots." A flat spot creates a linear indentation along the wheel curve, causing a rough ride.

A "flat spot" is attributed to user misuse and is not a manufacturing defect; thus, it is not covered under warranty as no wheels are tougher than asphalt.

Dehub

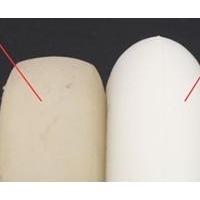

The image below displays two wheels: one relatively new with less than 30% wear and a completely new wheel.

If the relatively new wheel has minimal wear and the urethane has detached from the hub, this may indicate a manufacturing defect, as depicted here:

However, when a wheel shows over 40% wear and the urethane is damaged yet remains attached, it is generally not a manufacturing defect.

If you suspect a manufacturing issue, consult our claim guide to determine the necessary information for initiating a claim.

Return to Assembling a custom trick scooter

Return to Stunt Scooters explained here.