Bearings Purchasing Guide

Are you uncertain about which bearings to choose? This guide will clarify the key terms and important details concerning bearings. We will also advise on the optimal bearings suited for your particular style of riding or skating.

1. An Overview of Bearings

For a wheel to spin on its axle, it requires two bearings. Bearings significantly impact your speed and riding/skating experience.

Irrespective of your bearing type, steer clear of sand, water, and moisture, as these elements can drastically reduce your bearings' lifespan. Regularly cleaning and lubricating the bearings can improve their longevity and speed. Discover how to clean your bearings here.

A spacer is also necessary to occupy the gap between the bearings, preventing damage and ensuring smooth rotation once the axles are secured. The spacer's dimension is determined by the axle's size.

8 mm spacer

6 mm spacer

The calibre of bearings is influenced by several factors, including:

- Material

- Precision (ABEC)

- Lubrication

- Sealed or open (Removable Shield)

Determining the ideal bearings for you:

- If predominately riding/skating outdoors, we suggest sealed bearings with grease lubrication, as they best resist dirt & dust and demand minimal upkeep.

- For mostly indoor riding/skating, utilise open bearings that offer swift rotation and are straightforward to clean.

- If speed and long-distance travel are of interest, opt for high precision bearings using oil lubrication. They offer remarkable speed and ease of cleaning, though dirt can quickly impair them.

2. Installation

Typically, a bearing can be inserted with your thumbs. Correctly mounted, it will align evenly with the wheel core/hub. If it protrudes at one side, it is not properly mounted and could be damaged upon skating. For metal core wheels that are more challenging to mount, utilise a rubber hammer or a wooden block for assistance.

Never employ a metal hammer as it could damage the bearing and invalidate your warranty.

Optionally, some lubrication can assist in positioning a bearing, but all excess lubrication must be removed afterwards.

3. Exhaustive Insights on Bearings

Material

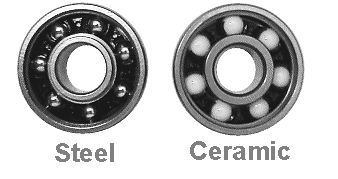

Materials play a pivotal role in the quality and durability of bearings. Most are manufactured from steel, but inexpensive bearings may use pressed sheet metal or hardened carbon steel, both unsuitable for extended life.

Superior bearings utilise genuine bearing-steel like chrome, titanium, or Swiss steel.

In ceramic bearings (often adopted for speed skating), the balls comprise industrial ceramic (Silicon Nitride). Ceramic balls rarely rust and often outlast steel.

Price typically correlates with quality where bearings are concerned, so reputable brands are generally reliable for producing robust bearings.

Precision/ABEC

Bearings are rated by the commonly accepted ABEC-standard, which indicates how efficiently they translate applied force. Higher ABEC classes elevate precision, efficiency, and speed potential, but don't inherently increase spin speed. ABEC ratings do not address crucial aspects like spacer and wheel precision, or material quality. All bearings degrade in precision over time.

Be aware that some brands do not use the ABEC system (e.g. Bones), and alternative rating systems exist.

ABEC stands for Annular Bearing Engineering Committee.

Lubrication

Bearings employ either oil or grease as lubrication, and must never operate without it; failure to do so could cause them to seize or slow down significantly.

- Oil: Offers high velocity due to lower lubrication resistance. A thin oil yields faster speeds but mandates more frequent upkeep.

- Grease: Better repels water and dirt compared to conventional oil. Almost no maintenance is needed, but it presents more resistance, thus less speed.

Note: Water can strip away lubrication. In such cases, when dry, bearings might overheat and become noisy or even melt during their next use, necessitating replacement. If they haven't been used meanwhile, they might be salvageable if properly cleaned and oiled before further use.

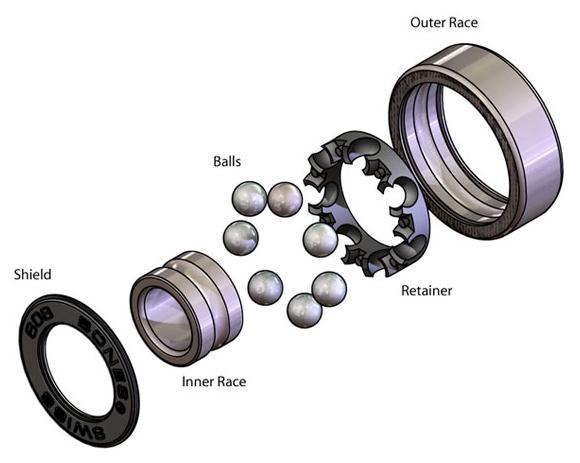

Shields/Sealings

To deter dirt, sand, and water from penetrating the bearings, a shield or seal is frequently installed on one or both sides of the bearing.

- A Shield is commonly a metal cover attached to the outer ring with slight clearance to the inner ring (also termed as a dustproof bearing). Bearings equipped with shields experience minimal friction, allowing greater speed, but aren't entirely insulated against water and dirt.

- A Seal (illustrated below) comprises steel-reinforced rubber affixed to the outer ring and lightly contacting the inner ring. It provides superior protection and minimal upkeep, albeit with increased friction and slightly diminished speed.

4. Explaining Standards and Bearing Precision

Factors encompassed by ABEC grades include eccentricity or the roundness of the inner ring's track. The table below illustrates the maximum eccentricity permissible.

| Type | mm | Inches |

| ABEC 1 | 0.0075 mm | (0.000295") |

| ABEC 3 | 0.0050 mm | (0.000197") |

| ABEC 5 | 0.0035 mm | (0.000138") |

| ABEC 7 | 0.0025 mm | (0.000098") |

| ABEC 9 | 0.0012 mm | (0.000047") |

This indicates that a higher ABEC rating corresponds to smaller deviations in bearing parts, resulting in more power transfer to the wheel.

ABEC and ILQ are not directly comparable since ILQ represents a brand name while ABEC denotes a standard.

ABEC ratings are based on production precision without addressing load durability or performance. Twincam, creators of ILQ, evaluate their bearings on a scale parallel to the ABEC scale. However, ILQ bearings feature 6 balls, whereas ABEC bearings contain 7.

To clarify, ILQ is not akin to a standard, unlike ABEC bearings. ILQ should, thus, be perceived as an unrated bearing by a professional inline bearing manufacturer and is unsuitable for industrial equipment.

Bones bearings are exclusively intended for skating - and are incomparable with ABEC standards.

Below is a terminology guide for bearings and their shields (bearing type is usually marked on the bearing with size, e.g., 608ZZ).

608

- Standard bearing

- 22 mm external diameter

- 7 mm width

- 8 mm internal diameter

688

- Mini/Micro bearing

- 16 mm external diameter

- 5 mm width

- 8 mm internal diameter

Z

- Shield, 1 metal shield

- Open on the opposite side for straightforward upkeep (oriented open side inward when mounting)

ZZ

- Shield, 2 metal shields

- Shields affixed with a minor C-ring, removable for maintenance access.

2RS/RS/RZ

- Seal, 2 steel-reinforced rubber seals

- Seals installed sans C-rings. Carefully detachable with a needle for maintenance.

BRS

- Seal, 2 steel-reinforced rubber seals (contact-free)

- Seals mounted without C-rings. Offers enhanced water ingress protection.